Agitator-Top Entry Agitator

Agitators-Top entry agitator

Description of top entry agitator

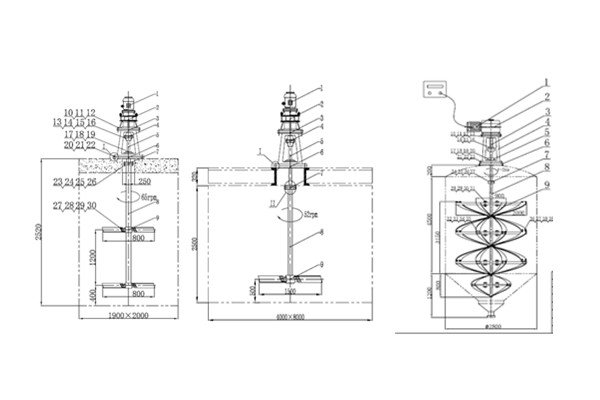

Top entry agitator is one of the most common forms of the mixing device, the stirring device is installed in the center line of cylinder or tank equipment, The type of drive usually adopts gear transmission or belt transmission. connected by a common motor or connected by reducer directly. The type of Impeller selected according to the purpose. Shaft seal mainly use packing seal, but for vacuum or higher pressure should use mechanical seals.

Top entry agitators drive by the belt transmission or gear transmission, connected with the motor or speed reducer directly, Impeller selected according to use; Generally using packing seal, but in a vacuum and under high pressure, should adopt mechanical seals. The structure of top entry agitator is simple, ease to install or dismantle. Suitable for medium and high speed mixing operation. Can also be equipped with a variety of rack used to seal device with pressure vessel stirring occasions, stirring shaft length and stirring paddle layer in a certain range can be arbitrarily chosen, due to the transmission, a supporting part above the liquid level can be used in sealed condition, also can according to user requirements to the installation of packing seal or mechanical seal assembly

CD’s top entry agitators are designed for a wide range of service in the chemical, pharmaceutical, mineral, water and wastewater, food and beverage, Flue Gas Desulfurization, power and other general process industries. The agitators feature a new, high-efficiency gearbox designed specifically for agitator service. Models are available in right angle and parallel shaft configurations to meet specific application requirements from critical chemical reactor systems to routine storage.

- the stirring device is installed in the center line of cylinder or tank equipment,

- usually adopts gear transmission or belt transmission

- In a certain range, the mixing shaft’s length and the number of the impeller layer can be arbitrarily selected

- because of the transmission and supporting part above the liquid level, Can be used without sealing conditions

- the structure is simple, easy to install or take down.

- Bulk chemicals

- Polymers

- Specialty chemicals

- Biofuels and bio refineries

- Hydrometallurgy

- water and wastewater

- food and beverage